+251 99 380 2995 | +251 97 022 2227 | [email protected]

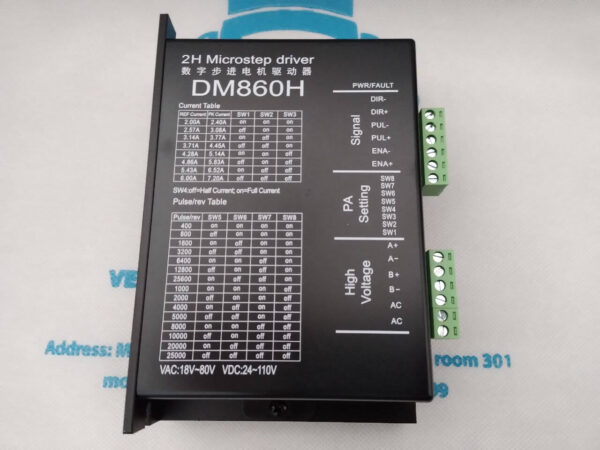

DM860H Stepper Motor Driver

Br 11,500.00

- Model Number : DM860H

- Power supply voltage DC24-110V or AC18-80V

- Can drive 4,6,8 line two-phase stepper motor

- Subdivision range: 400~25000

- Pulse response frequency: 200KHZ

- Drive current 2.4-7.2A, resolution: 0.1A

- Optically isolated signal input

- Motor noise optimization function

- It can drive any two-phase and four-phase hybrid stepping motor with a phase current of 2.0A or less

- 7.20KHz chopping frequency

- Overcurrent, overvoltage, undervoltage, short circuit protection to insure safety operation.�

- Apply in dispensing machine, woodworking machine, welding machine, screw machine, winding machine, placement machine, packaging machine, engraving machine , LED, electronic equipment, etc.

- High‑speed response microstepper motor, the speed is doubled compared with analog chip. The DM860 is the latest chip for DSP driver that features of high performance, high turning moment, low noise, and strong anti-interference ability

- DM860H Stepper Motor Driver

- DMA860H The driver adopts differential interface circuit applicable to differential signal, single-terminal common negative and common positive interfaces, built-in high-speed optocoupler, allowing the reception of long line driver, collector open circuit and PNP output circuit signals. In harsh environments, we recommend the use of long – line driver circuit, strong anti – interference ability.

- Pulse control signal: the pulse rising edge is effective; PUL- 4 ~ 5V at high voltage and 0 ~ 0.5v at low voltage. To reliably respond to pulse signals, the pulse width should be greater than 1.2 microns. Series resistance is required if 12V or 24V is used.

- Direction signal: high/low level signal. To ensure reliable commutation, the direction signal should be established at least five microns before the pulse signal. The initial running direction of the motor is related to the wiring of the motor. Interchanging any phase windings (such as A , A- switching) can change the initial running direction of the motor, DIR- 4 ~ 5V at high voltage and 0 ~ 0.5v at low voltage.

- Enable signal: this input signal is used to enable or disable. When ENA is connected to 5V and ENA- is connected to low level (or internal optocoupler conduction), the driver will cut off the current of each phase of the motor to make the motor in a free state.

- CNC DSP Digital Microstep driver DM860H Stepper Motor Controller 2-phase Digital Stepper Motor Driver for Nema 23 Nema 34 series stepper motor

- Parameter self-tuning algorithm, motor adaption;

- High Segmentation

- Small vibration, low heat, smooth running

- high speed torque compensation

- Current vector control, high efficiency

- Acceleration and deceleration control improves the smoothness of start-stop.

- Single and double pulse control mode can be selected.

- Motor working position memory

- Differential signal input optical decoupling, compatible with 5V ~ 24V.

- custom user segmentation

- Currently, subdivision dialing is convenient.

- Over-current, over-voltage protection, under-voltage protection;

- Green light means run, red light means protect or not work.

- Suitable for all kinds of small and medium-sized automation equipment and instruments, such as: laser processing equipment, engraving equipment, measuring equipment, electronic processing equipment, textile and clothing equipment, special machine tools, packaging machinery and equipment, etc. The effect is better when used in equipment where users expect low vibration and low noise.